Vapometallurgy Solutions

VAPOR-PHASE METAL ADDITIVE MANUFACTURING

Development of new metal AM materials

VAPOR-PHASE METAL ADDITIVE MANUFACTURING

Development of new metal AM materials

VPM Research is involved in nickel vapometallurgy consulting and in the development of new feedstock materials for metal additive manufacturing.

Certain metals form unique organometallic compounds that can be used as precursors to produce solid, fully dense metal deposits at near-ambient conditions. This process has been employed commercially since early 1900’s in the production of high purity Ni, Fe and FeNi products (“Mond process”) and more recently, in the production of integrated electronic circuits.

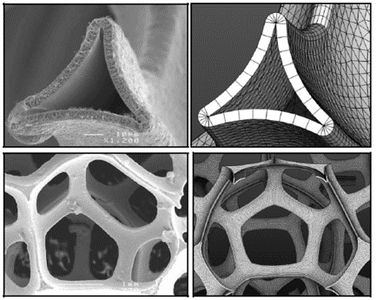

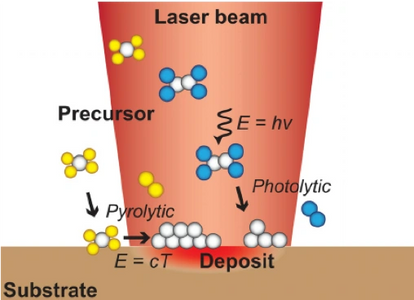

One category of LCVD processes involves photolytic and pyrolytic decomposition of organometallic precursors, such as nickel and iron carbonyls. It is possible to control the process so that photolytic decomposition is suppressed (effectively zero) and the process becomes 100% pyrolytic, forming precise, solid metal deposits at ~200 degrees Celsius based on the laser beam location. The above image shows a sample of LCVD-produced nickel on the surface of an open-cell polyurethane foam structure.

Utilizing vapor-phase precursors of metals in purpose-designed, chemical vapour deposition (CVD) 3-D printers enables the formation of complex, high-precision, controlled microstructure 3-D metal objects with unique properties.